Duplex stainless steel cables for special requirements

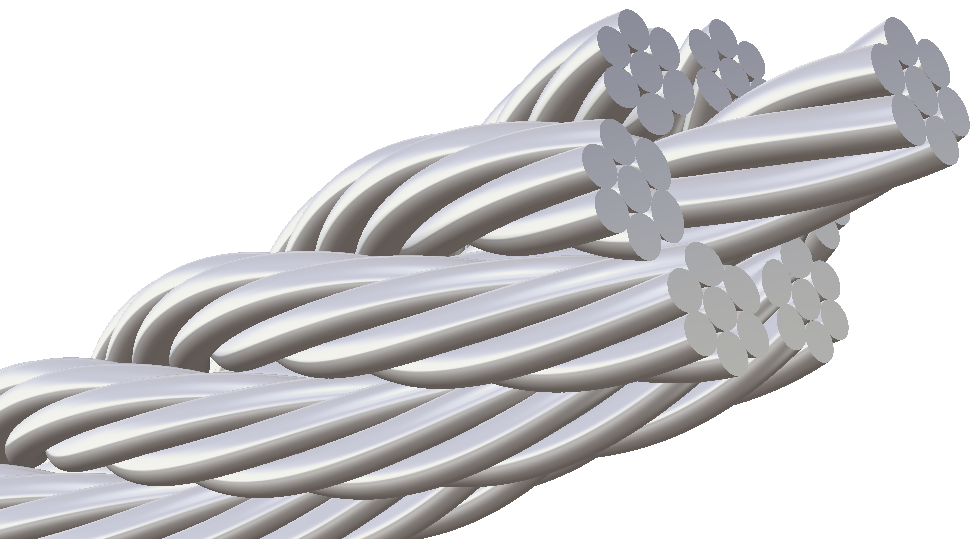

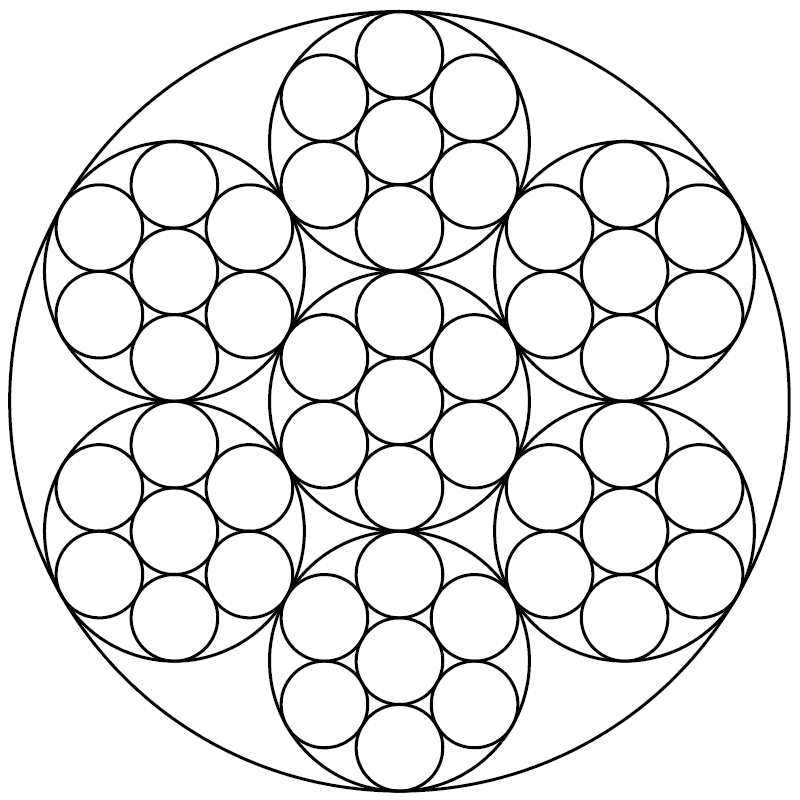

When standard stainless steel such as 1.4401 reaches its limits, it is advisable to use duplex stainless steel. The high-quality stainless steel with the designation 1.4462 offers excellent corrosion resistance and is ideal for chloride-containing, acidic, and alkaline environments. We offer duplex stainless steel cables in the proven 7×7 construction and optionally with end fastenings and coating.

Properties: Duplex stainless steel 1.4462 can be used at temperatures ranging from –100°C to +250°C, is slightly magnetic, and offers impressive strength and resilience. At the same time, it provides excellent corrosion resistance and mechanical properties, ensuring that it remains reliable even under dynamic stress and in aggressive environments.

Application: The material is particularly suitable for applications requiring a high level of corrosion resistance. It is used reliably in industry and construction as well as in offshore and maritime applications.

Surface: As with conventional stainless steel cables, the surface of the duplex stainless steel cables is high quality and can be provided with an additional protective coating if required. This ensures that the cables retain their attractive appearance and are optimally protected against external influences.

Versions Hamburger Drahtseilerei: We offer duplex stainless steel cables in a standard 7×7 construction in diameters of 1.5 mm, 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, and 8 mm. Other diameters and constructions are available on request. On request, we can supply any variant with suitable end fittings and coating.

| Construction | Diameter [mm] | Weight [kg/100m] | MBK 1570 [kN] | MBK 1770 [kN] | MBK 1960 [kN] |

|---|---|---|---|---|---|

| 7×7 | 1.5 | 0.88 | 1.55 | 1.5 | |

| 2 | 1.57 | 2.75 | 2 | ||

| 3 | 3.53 | 6.18 | 3 | ||

| 4 | 6.28 | 10.99 | 4 | ||

| 5 | 9.82 | 15.23 | 5 | ||

| 6 | 14.14 | 21.93 | 6 | ||

| 8 | 25.13 | 29.85 | 8 |

Comparison: Materials 1.4462 & 1.4401

| Duplex stainless steel | Stainless steel | |

|---|---|---|

| Material | 1.4462 / AISI 318LN | 1.4401 / AISI 316 |

| Operating temperature | -100°C – 250°C | -200°C – 500°C |

| Corrosion resistance | excellent | very good |

| Mechanical properties | excellent | middle |

| Potential areas of application | Offshore & marine industry | Maritime applications / shipbuilding |

| Shipbuilding | Chemical & pharmaceutical industry | |

| Mechanical engineering | Food & paper industry | |

| Construction industry | Architecture & construction | |

| Food & paper industry | Wastewater & environmental technology | |

| Bridge construction | Transport & lifting technology | |

| Hydropower & energy plants | Mechanical engineering | |

| Petrochemical industry | Automobilindustrie | |

| Wastewater & environmental technology | Petrochemical industry | |

| Transport & lifting technology | Decorative purposes |

When duplex stainless steel is the better choice instead of standard stainless steel

Standard stainless steel such as 1.4401 (AISI 316) is the norm in areas of application such as construction, the food industry, and maritime applications due to its excellent corrosion resistance. However, its limitations become apparent as soon as more aggressive media or high mechanical loads come into play. In such cases, we recommend the material 1.4462 (AISI 318LN). This combines significantly higher strength with excellent resistance, especially in chloride-containing or chemically stressed environments. Specific areas of application for 1.4462 are:

In other words, wherever 1.4401 stainless steel reaches its limits—for example, due to high chloride exposure, aggressive chemicals, or heavy use—1.4462 duplex stainless steel offers significantly longer service life and greater safety. If you are unsure which material is best suited for your rope, please contact us—we will be happy to help you.

When duplex stainless steel meets 7×7 – an unbeatable combination

The combination of 1.4462 duplex stainless steel with the proven 7×7 construction brings together the best of both worlds: maximum strength and corrosion resistance with maximum flexibility and flexural fatigue strength. This combination ensures that the ropes remain reliable even under dynamic loads, are easy to handle, and retain their shape and function over the long term. Whether in industrial applications or demanding maritime environments, the 7×7 construction makes duplex stainless steel ropes particularly robust, durable, and versatile.

Duplex ropes with matching end fittings

In the offshore industry, for example, when securing lifting systems on drilling platforms, heavy loads must be held and transported reliably. To ensure that this works flawlessly and safely, suitable end fittings such as eyelets, thimbles, and clamps are essential. Our ready-made solutions offer you maximum safety, corrosion protection, and immediate readiness for use.

Hamburger Drahtseilerei provides you with a complete, high-quality system from a single source. We look forward to advising you.

FAQs – Duplex stainless steel cables

Contact us

Would you like more information about our production or do you have questions about our products? Would you like to find out more about our accessories? Simply get in touch with us – we look forward to hearing from you!

Hamburger Drahtseilerei

Hamburger Drahtseilerei A. Steppuhn GmbH

Klaus-Groth-Straße 15

D-23843 Bad Oldesloe

+49 (0) 4531 / 8990 – 33