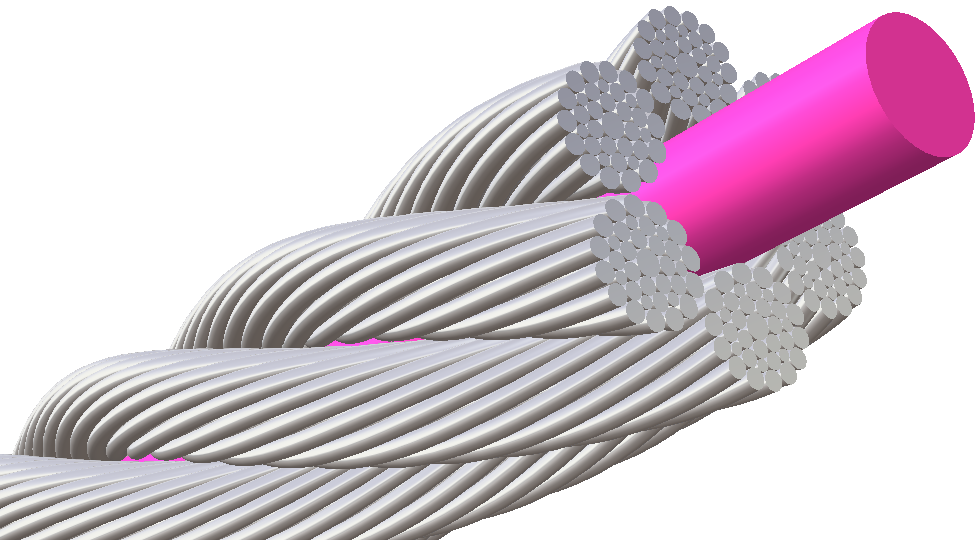

6x36WS+FC – flexible & stable wire rope for dynamic applications

The 6×36WS+FC design is suitable for applications that require a balance between flexibility and structural stability. A characteristic feature is the Warrington-Seale arrangement of the strands, which makes the rope resistant to uneven loads. The construction is supplemented by a fiber insert, which enables the rope to run particularly smoothly over rollers and drums. Find out more about this construction below. If you have any questions, please call us or send us a message – we will be happy to help.

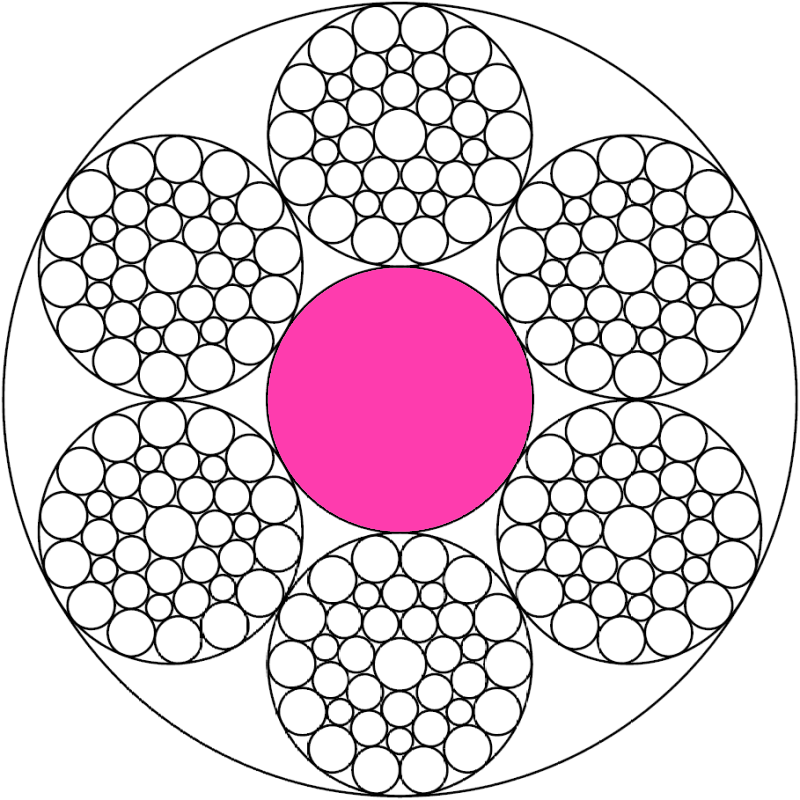

Designation: The design consists of six strands, each with 36 wires in a Warrington-Seale arrangement (WS). This special combination of wires of different thicknesses within the strand ensures a dense, resilient structure. In the center of the rope is a fiber core (FC), which provides elastic support for the rope.

Properties: Thanks to its Warrington-Seale construction, the wire rope has a particularly uniform surface structure. This improves pressure distribution on rollers and drums and reduces localized wear. The fiber insert also has a damping effect and supports smooth, controlled rope running under dynamic loads.

Application: The construction is very well suited for rope systems with regular deflection, drum operation, and changing pull directions. 6×36WS+FC shows its strengths particularly where ropes must not only run flexibly but also remain dimensionally stable.

Material: Available in galvanized version for industrial applications and for outdoor use in normal weather conditions (avoid extremely corrosive conditions).

Versions at Hamburger Drahtseilerei: On request, we can also supply the wire rope with coating and/or custom-made end fastenings.

| Construction | Diameter [mm] | Weight [kg/100m] | MBK 1570 [kN] | MBK 1770 [kN] | MBK 1960 [kN] |

|---|---|---|---|---|---|

| 6x36WS+FC | 1 | 0,38 | 0,52 | 0,58 | 0,65 |

| 2 | 1,51 | 2,07 | 2,34 | 2,59 | |

| 3 | 3,4 | 4,66 | 5,26 | 5,82 | |

| 4 | 6,05 | 8,29 | 9,35 | 10,35 | |

| 5 | 9,45 | 12,95 | 14,6 | 16,17 | |

| 6 | 13,61 | 18,65 | 21,03 | 23,28 | |

| 7 | 18,52 | 25,39 | 28,62 | 31,69 | |

| 8 | 24,19 | 33,16 | 37,38 | 41,4 | |

| 9 | 30,62 | 41,97 | 47,31 | 52,39 | |

| 10 | 37,8 | 51,81 | 58,41 | 64,68 | |

| 11 | 45,74 | 62,69 | 70,68 | 78,26 | |

| 12 | 54,43 | 74,61 | 84,11 | 93,14 | |

| 13 | 63,88 | 87,56 | 98,71 | 109,31 | |

| 14 | 74,09 | 101,55 | 114,48 | 126,77 | |

| 15 | 85,05 | 116,57 | 131,42 | 145,53 | |

| 16 | 96,77 | 132,63 | 149,53 | 165,58 |

Warrington Seale – why this design is crucial

Warrington Seale describes a special strand structure with wires of varying thicknesses that stabilize each other. This creates a very compact strand with high resistance to deformation. Thanks to this design, internal friction is reduced and a more even load distribution is ensured. This is a decisive advantage, especially for winches, pulleys, and multi-layer winding. WS constructions are therefore the preferred choice when smooth running and a long service life are required.

Robust, durable, dynamic – suitable for many applications

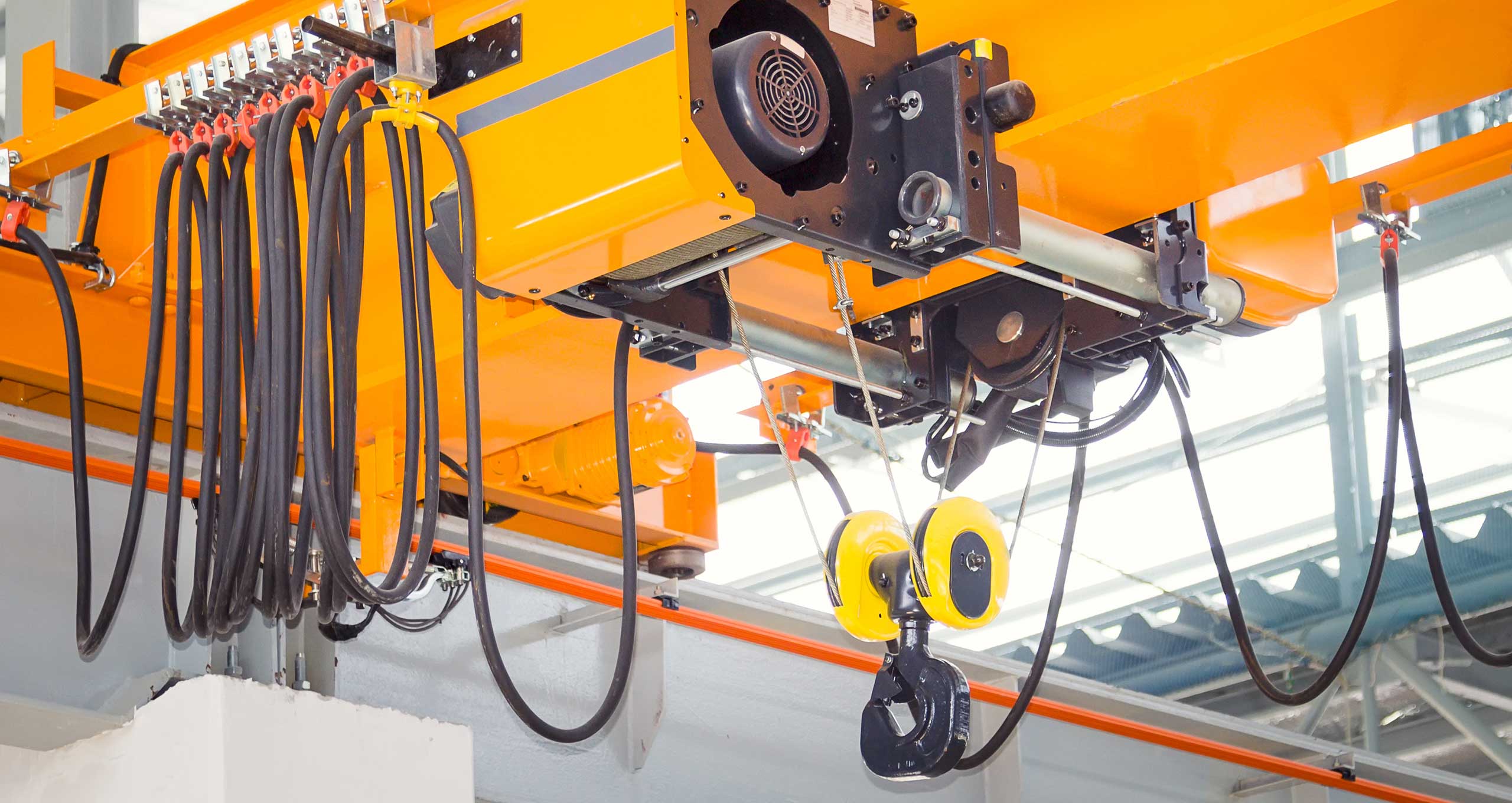

6x36WS+FC – the perfect design for use in winches

The 6×36WS+FC wire rope design is ideal for use as a winch rope in industrial applications. The compact strand structure ensures clean winding and minimizes the risk of constrictions on the drum. At the same time, the fiber insert supports uniform yielding under load. The rope remains stable and runs smoothly even with frequent changes of direction. Click on the button to learn more about this and other winch ropes.

Without Warrington Seale, but with fiber insert – when is 6×37+FC the better choice?

Compared to 6×36WS+FC, 6×37+FC is designed even more for maximum flexibility. Due to the higher number of fine individual wires, 6×37+FC is particularly suitable for applications with extremely small deflection radii. If the focus is less on structural stability and more on the softest possible bending behavior, this design has the advantage. 6×36WS+FC, on the other hand, scores points for its smooth running and higher dimensional stability. The choice therefore depends heavily on drum size, deflection, and load profile. We would be happy to advise you on the optimal design for your requirements.

End connections, coating, sold by the meter – we cater to individual requirements

Whether sold by the meter, with protective coating, or with pre-assembled end connections – 6×36WS+FC can be flexibly adapted to your application. We assemble the rope exactly according to your technical specifications. We also reliably implement special lengths or special connections. At Hamburger Drahtseilerei, you receive a ready-to-install solution without additional assembly work. If you have any questions about design or application, we will be happy to advise you personally.

FAQs – 6x36WS+FC steel cables

Contact us

Would you like more information about our production or do you have questions about our products? Would you like to find out more about our accessories? Simply get in touch with us – we look forward to hearing from you!

Hamburger Drahtseilerei

Hamburger Drahtseilerei A. Steppuhn GmbH

Klaus-Groth-Straße 15

D-23843 Bad Oldesloe

+49 (0) 4531 / 8990 – 33